Upgrading from a hose end timer to a professional grade drip irrigation system.

New York Plantings Irrigation and Landscape Lighting NYC utilizes professional industry standard irrigation system components and new updated WFI smart irrigation controllers.

Protect your landscape and garden investment with reliable high-quality professional grade drip irrigation system components from NewYorkPlantings.com

|

| NYC Drip Irrigation System Installation Service Truck and Gardening Service NewYorkPlantings.com |

This is more of a chat than an actual blog. I will write those another time. Today I want to discuss some of what to look for in a quality drip irrigation system installation and even how your installation should look when completed. I also want to drive the point home that if you have a battery powered hose end irrigation system timer it is time to consider an upgrade.

We would like to upgrade YOUR irrigation system! ...Upgrading your drip irrigation system is key to peace of mind that your landscape investment is protected by removing the hose end battery powered timer or removing the battery powered Hunter Node that some NYC garden guy sloppily installed. (a Hunter Node CAN be used in a professional grade irrigation system, just that most Node irrigation controller installations we see in NYC are not installed by professional irrigation system mechanics and lack the basic components widely recognized as the standards of professional irrigation system installations.)

Which to use? The choice for high end gardens is obvious:

|

| Do you have one of these Hose End timers? Better than nothing, many different brands and models but may be a shortcut in reliability. |

So, Upgrading drip irrigation systems...this isn't really and upgrade as it is the right way or the best way to install an irrigation system in the first place by including the parts and assembly as universally accepted throughout the irrigation industry, throughout the USA. In this writing I will focus more upon the controls. This means the parts that turn on and off the water in your automatically controlled drip irrigation system and keep it shut off until you want it watering your garden again.

Textbook standard of drip irrigation system design that is neatly installed and securely mounted. When you look at our "newyorkplantings" professional grade drip irrigation system installation work, you feel good because you know it was installed with care and pride by the team at New York Plantings Irrigation and Landscape Lighting NYC. If you would like to know more about our company, please see the website at NewYorkPlantings.com

The components that New York Plantings Irrigation uses include some of the same valves and manifold parts seen in the 20 (or more) year old irrigation systems installed even before we became a NY drip irrigation service company however the internal materials of irrigation system valves have been improving over the years.

Let's just say you have a high end home with nice landscape, a hot sunny terrace or landscape that is an investment of time and several thousand dollars. Let's say that you would like to protect this investment in your NY or any city penthouse terrace garden or townhouse landscape, or anywhere you have need for a drip irrigation system.

If you have a battery powered timer/controller referred to as a "hose end timer" we already should be in agreement that the setup you have is temporary and not up to the standard of reliability nor the other things of you home. Sure, there will be those telling us they used them for years...yeah well they recycled used toothbrushes and q-tips for years too...Hose end irrigation system timers for the most part simply are not as reliable and not a standard of irrigation system design. Besides, I always want to at least know the best available for whatever I am doing and make an informed decision.

Let's just say you have a high end home with nice landscape, a hot sunny terrace or landscape that is an investment of time and several thousand dollars. Let's say that you would like to protect this investment in your NY or any city penthouse terrace garden or townhouse landscape, or anywhere you have need for a drip irrigation system.

If you have a battery powered timer/controller referred to as a "hose end timer" we already should be in agreement that the setup you have is temporary and not up to the standard of reliability nor the other things of you home. Sure, there will be those telling us they used them for years...yeah well they recycled used toothbrushes and q-tips for years too...Hose end irrigation system timers for the most part simply are not as reliable and not a standard of irrigation system design. Besides, I always want to at least know the best available for whatever I am doing and make an informed decision.

We at NY Plantings Irrigation usually explain the difference between an economy irrigation system and a professional grade system.

I'm not sure how technical of an explanation you want or simply trust that we at #newyorkplantings Irrigation system services in NYC do what we say we will...or, perhaps you already know about irrigation systems and plumbing from owning homes with landscaping and outdoor spaces and can see the difference in our work vs. others who just want to make a buck so "yeah we 'do' irrigation too!"

Good valves for your irrigation system:

There are many brands of valves available and most are made for lawn sprinklers. We sometimes use different brands for certain installations.

These pictured 3/4" Toro drip irrigation system valves are proven the most reliable and used by the top 3 drip irrigation system specialists in NYC , NewYorkPlantings and 2 other guys.

The 3 of our companies do the best work in the city. Neat, reliable and professional installations. Each has their own personality but we all have a high standard and also have an edge of broader scope of services, much higher mechanical and decades of garden know how.

The 3 of our companies do the best work in the city. Neat, reliable and professional installations. Each has their own personality but we all have a high standard and also have an edge of broader scope of services, much higher mechanical and decades of garden know how.

The "other guys" who install irrigation systems are either lawn sprinkler folks or non mechanical (to say the least) gardeners who 'dabble' in drip irrigation...and it shows in their work. Yes, you can take a tube and place it in a planter or pot, leave it all over the ground, a tangled mess of wire and tubing, loose connections and home depot parts, add a $15 dollar battery powered "hose end" timer (to protect a $50K garden planting, charge the customer thousands for an "irrigation system" then, water comes out, temporarily and if you call that something you can charge people for...then, the reliable professional grade drip irrigation system the client should have received is yet to come, although at the expense of a new garden.

For some NYC outdoor space owners who had "lawn sprinkler companies" come to their house, the parts are retrofitted or converted lawn sprinkler stuff, like that spider looking thing with 5 lines going into the back of your planters, plumbing valves that belong inside (like that huge anti return valve someone stuck on your system, which you already have inside the house!) and thick back 3/4" rigid plastic pipe circling your terrace.

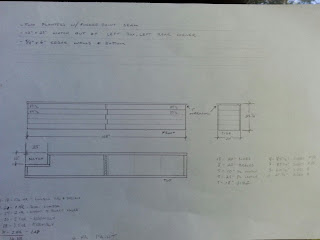

Here is a typical system I assemble: Note that there is no weight on the spigot which causes the little 1/2 inch copper pipe to crack at the solder joint and leak into the wall...We use a simple burst proof hose. Then a dura-manifold is one more place where we differ from our competitors. The others use threaded fittings throughout which is fine except their workers do not have much skill besides the limited scope and very often cross thread, chew up and botch the assembly, making service a nightmare or expensive.

*We use O-ring sealed connections on our drip irrigation systems that can be serviced easily and never leak. This is used in hot tubs and other systems. In the rare instance of valve failure, the valves are easily replaced by turning the large plastic nut.

*We install a high pressure filter BEFORE the drip irrigation system but others install either afterward or do not install at all. Dirt is about the only thing that will cause issues in these valves. *There is an incorporated pressure regulator that makes the drip emitters last longer and keeps parts, held together by barbed fittings, from separating downstream due to pressure spikes.

*All wires are tied, connected with a silicone grease filled waterproof wire nut (ALL of our competitors' irrigation system wiring is sloppy and begins to oxidize at wiring connections within days of install because they use the cheapest wire nuts available made for indoor use) In fact, I want to write blogs about drip irrigation but then these wannabees often copy our work.

More differences from the setup you have now:

Separate valves: Called solenoid valve as well, These last decades, solid open/closing. Low priced battery timers often leak and stay open. The pressure seems fine and we can continue to run one zone however the new setup will have 2 valves.

Safety valve: Sometimes called a main valve, A safety valve protects the entire system in case the rare instance of a "continuous run" situation should occur. This is standard of the professional industry however the inexperienced and ill advised will set up irrigation systems without this valve. You will never see an experienced irrigation company forego a safety valve. There is even provision on pro grade timers to control this valve.

So this is some of the reason why the system will be upgraded. The battery powered setup you have will last a season or two and is realistic to say that these become stuck open or closed, cannot be relied upon when travelling and are not able to make the automatic adjustments that new "smart irrigation controllers" can.

*Timer: I suggest just going with the new "WIFI" irrigation system controllers. They also use Bluetooth. You do not have to use the WIFI feature unless you wish to. There is an app for your phone to match the controller. No more going outside to adjust the controller, asking others...or even going home!

These are great, have excellent customer support, several videos in their use and warranty and the bugs are all worked out.

You operate either old school on the timer or with your phone from anywhere in the world. You can pause if raining, add a shot of water if hit or set the timer to monitor local weather and pause during rainy days!

We no longer need rain sensors however there is still provision for sensors...even soil moisture sensors. You will be alerted if irrigation is not functioning as well.

Photo from Orbit co. of a WIFI Capable Irrigation System Controller-Timer Often used by New York Plantings Irrigation and Landscape Lighting NYC

For a 2 zone system, this upgrade, at the time of this writing:

About $2390.00 in total complete and includes a 2 year warranty. The only way that we will not replace or repair a damaged system for free is if the system was not Winterized properly. If we winterize the system and it is damaged by freezing then we replace the damaged system parts again for free.

We will include the first Weatherization (Fall shut down) at no charge.

This is why our irrigation company has a near 5 star rating on google compared to our garden company with 4.

New controller, manifold, valves, and connections, neatly installed in a way that matches the rest of the property.

We keep this all in stock on our service trucks and do not need to order anything for any service or installation.

Contact us at New York Plantings Irrigation and Landscape Lighting for your irrigation system services, Landscape Lighting and as most already know, Unmatched garden design and installations from our parent company: NewYorkPlantings.com

Todd Nappi New York Plantings Irrigation.

6464348049

6464348049

|

| A drip Irrigation system Manifold being assembled by NewYorkPlantings Irrigation and Landscape Lighting NYC go to newyorkplantings.com |

|

| Install an automatic drip watering system for your penthouse terrace garden: Make sure to buy a professional-grade Drip irrigation system by New York Plantings Irrigation and Landscape Lighting NYC. |

|

| Neatly installed professional Grade Drip Irrigation 2 zone System by New York Plantings Irrigation NYC go to newyorkplantings.com |

Landscape lighting, planting as master gardener and other work in outdoor space improvements.

|

| A Mercer street New York, NY Roof Garden Installed by New York Plantings Garden Designers and the Irrigation Company in partnership. NewYorkPlantings.com There |